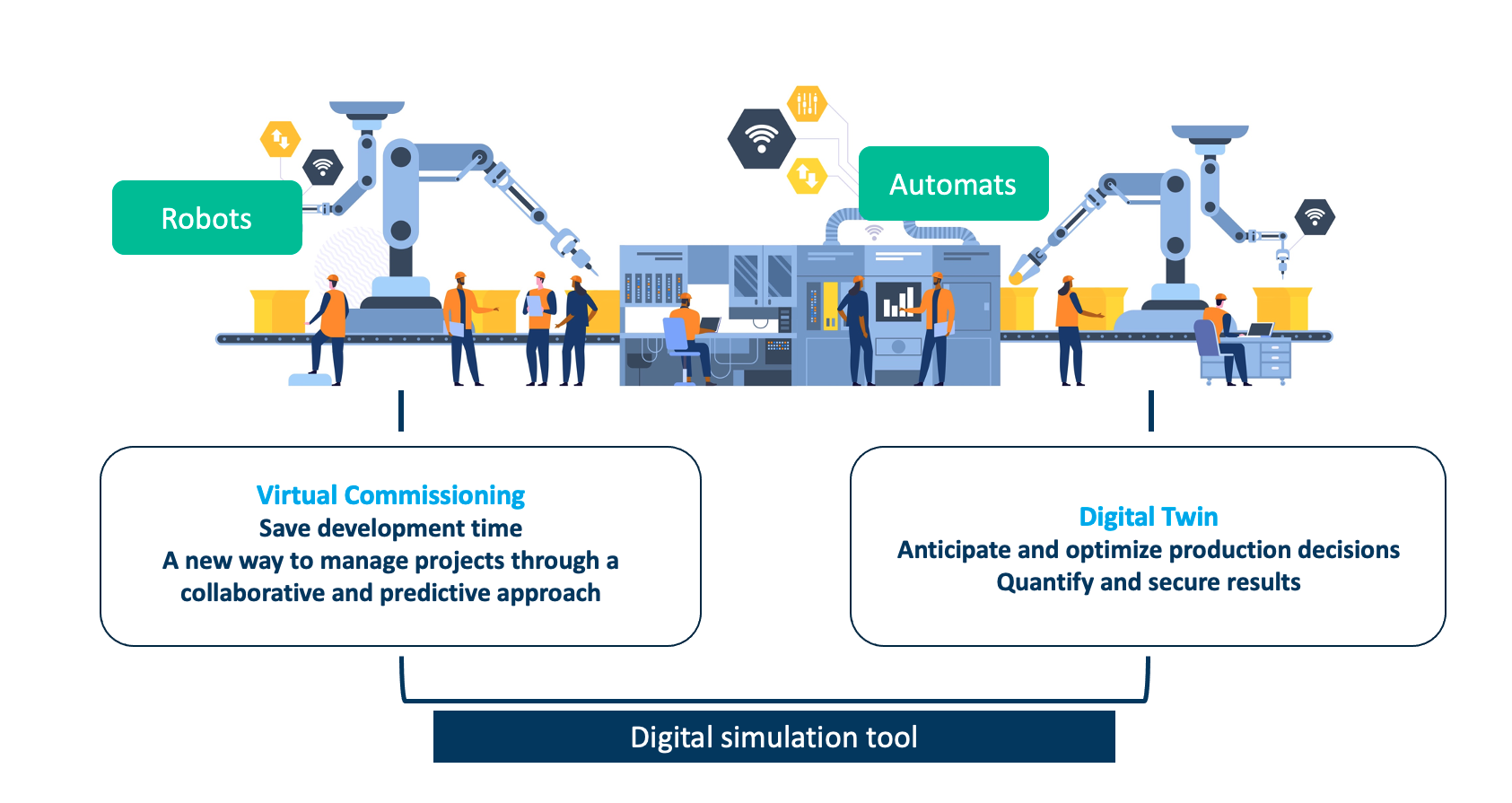

Virtual commissioning

Anticipate and optimize your industrial performance

Today’s industrial companies have to be reactive to meet the demands of competitiveness, changes and diversifications. This reactivity requires the optimization and evolution of the design and commissioning cycles of the industrial tool. Virtual commissioning is the solution that enables this transformation. It gives project teams the opportunity to work collaboratively earlier in the project, even before the industrial process is launched. It also provides the opportunity to improve decision making based on concrete and measurable elements coming from modeling and simulation.

Virtual commissioning: anticipate and optimize your industrial performance

Virtual commissioning is using simulation and numerical modeling to perform tests on a virtual process in order to anticipate the real behavior during its commissioning to:

The gain is visible on development costs, commissioning costs (travel + downtime), rework costs, but also on project risk aspects

Where can virtual commissioning be used?

In the industrial cycle, it is possible to use these combined technologies in the following cases:

- Programs and logic development for industrial line management,

- Validation tests of automation programs before commissioning (functional and safety),

- Tests of production line evolutions without impact on current production.

Inoprod supports you in the optimization of the production system performances

Definition and creation of the Digital Twin

Inoprod supports you in the definition and realization of your Digital Twin and assists you in:

Training and integration of software solutions

Inoprod can support you in the training and skills development on the software and methodologies of virtual commissioning deployment.

They trust us

Mecatherm

More flexible and efficient production lines with Tecnomatix® Plant Simulation.

Learn more

Comau

Securing the production and performance of a production line by a dynamic simulation

Learn more