Aerospace

The aerospace industry is a major source of innovation and technological progress. This industry plays an essential role in national defense, enables safe and efficient air travel, increases communication and the dissemination of knowledge. However, it is also an industry that has faced many uncertainties and disruptions in the past years. Despite this uncertain context, it is necessary to make the necessary efforts to modernize sites, digitize production tools, optimize product design, which will help your organization to be more competitive.

Examples of projects performed by our experts

FAA certification - Simulation and finite element sizing of aircraft seats

Safran Seats is one of the leaders in the aerospace industry and develops different categories of seats, ranging from crew seats (pilot, co-pilot, hostesses, etc.) to different versions of passenger seats (luxury, business, economy, etc.). The certification of passenger and crew aircraft seats requires both static and dynamic test campaigns. As part of the development of new seats, Safran Seats relied on the expertise of Inoprod to create a finite element model of a hostess seat. The challenge is to reproduce and improve the behavior of the seat to obtain compliance certification issued by the FAA (Federal Aviation Administration).

Optimization of an industrial site & validation of capacity

As part of the growth of its activities, our client (specialized in composite, metallic and hybrid structural assemblies for the aerospace) requested to enter into a reasoned approach to the development of its industrial organization in order to respond to the “ramp-up” imposed by its industrial development plan and to confirm the production capacity of its future industrial organization. Through risk analyzes and flow simulation, Inoprod has enabled our client to:

- Identify process risks allowing it to better control its production

- Secure the sizing of its production tool and implantation areas to achieve its capacity objectives

Implementation of an improvement plan to reduce WIP levels

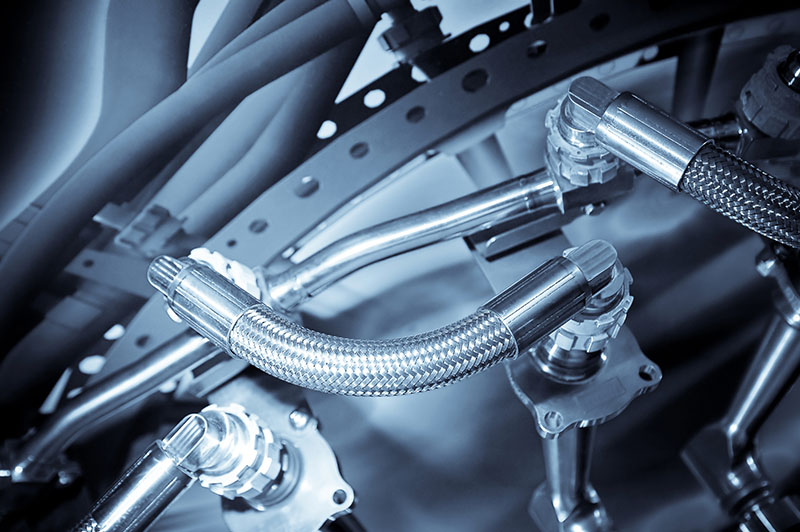

To deal with dysfunctions that have become time-consuming (high levels of WIP, excessive stress on the teams, etc.), our team has been requested to set up a continuous improvement program for a company specializing in the achievement of sections of fluid distribution circuits integrated into aircraft. In this context, we realized an analysis of the entire industrial process of the site (production, quality, supply chain and industrial methods), to establish an action plan and correct the observed dysfunctions.