The company ACB Pume is specialized in boiler making, subcontracting and the realization of accessories for the sectors of public works and agriculture.

Within the framework of the development of new couplings intended for public works, ACB Pume wishes to optimize and validate the new designs of its bucket clamps which integrate the following components: Bucket & Coupler.

The construction of a numerical model by finite element, via the Ansys Workbench software, allowed Inoprod to simulate the behavior of the product in its context of use in order to highlight possible failures and optimizations. The objective is to avoid these risks and to secure the production launch of a validated design.

Simulation objectives

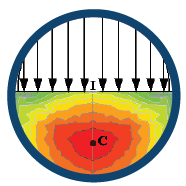

- Simulate the mechanical behavior of the bucket/coupler assembly during critical product life phases: Cavage, Striking Effort, and Lifting.

- Analyze the displacements and stresses in each of the components, for each load case, to highlight the undersized areas on which optimization was necessary.

- Propose and define optimization paths in the case of identified undersizing.

Technical solutions proposed

Optimization of the geometrical shape:

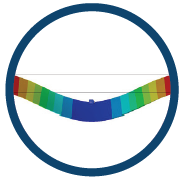

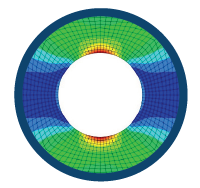

- The coupler to limit deformation and stress

- Lifting lugs to meet lifting requirements

Reinforcement of the welded area between coupler and bucket to limit punching.

Key indicators

Travel under load

Von Mises constraints for each component

Hertz pressure

They trust us

Mecatherm

More flexible and efficient production lines with Tecnomatix® Plant Simulation.

Learn more

Comau

Securing the production and performance of a production line by a dynamic simulation

Learn more

Make an appointment with an expert

Or contact us : +33 (0)4 73 27 20 89 (FR) / +1 (438) 921-5381 (CA)